The Growing Case for Chinese Products in the Caribbean

A balanced examination of how Chinese manufacturing—from prefab housing to electric vehicles—could be the key to unlocking Caribbean development.

Introduction: Beyond the Stereotypes

For decades, the phrase "Made in China" carried a heavy stigma. It was shorthand for cheap, disposable, and unreliable. But if you are still holding onto that view in 2025, you are looking at a world that no longer exists.

The reality on the ground has shifted dramatically. As the Caribbean wrestles with a severe housing crisis, crumbling infrastructure, and the crushing cost of living, we cannot afford to ignore the solutions sitting right in front of us. It is time for a serious, evidence-based conversation about what Chinese manufacturing can actually offer our region.

This isn't about blind advocacy. China’s manufacturing sector still has its warts—quality control issues and regulatory gaps are real. But dismissing Chinese products wholesale means turning our backs on potentially the most effective tools we have to solve our development problems. The data tells a nuanced story, and it’s one that Caribbean policymakers, businesses, and consumers need to hear.

The Caribbean's Infrastructure Crisis: A Perfect Storm

Before we talk solutions, let’s be honest about the scale of the problem. We are facing a regional emergency.

Housing: The Numbers Don't Lie

According to the IDB, roughly 23 million people in Latin America and the Caribbean face a housing deficit. That’s not just a statistic; that’s millions of families without a decent roof over their heads. In many of our cities, land prices double every decade, while incomes stagnate. Building a traditional home is becoming a fantasy for the average citizen, with mortgage credit sitting at a dismal 8% of GDP.

Infrastructure: Falling Behind

A 2024 study by CAF revealed the cracks in our foundation:

· Energy: Only 15% comes from renewables, keeping our electricity bills sky-high.

· Water: We lose nearly half our water (45%) to leaky, outdated pipes.

· Sanitation: Sewage treatment coverage is a shocking 11%.

To fix this, we need to invest about 6.2% of our annual GDP. Right now? We’re barely managing 2.3%. Traditional aid and government budgets simply cannot bridge that gap. We need a new approach.

The Chinese Manufacturing Evolution

While we’ve been struggling, China has been evolving. By the end of 2024, nearly 93.93% of Chinese manufacturing goods met national quality standards. This isn't an accident; it's the result of massive investment in AI, robotics, and rigorous ISO certifications.

The Apple Paradox: Think about the phone in your pocket. Tim Cook, CEO of Apple, has said plainly that they manufacture in China not because it's cheap, but because of the skill. The same country that makes "cheap plastic toys" also manufactures the most premium electronics on earth. The difference isn't the country; it's the buyer's strategy.

Case Study 1:

Prefab Housing—A Game Changer

Imagine building a home in weeks, not months, for a fraction of the cost. Chinese prefab manufacturers are making this a reality.

The Value Proposition:

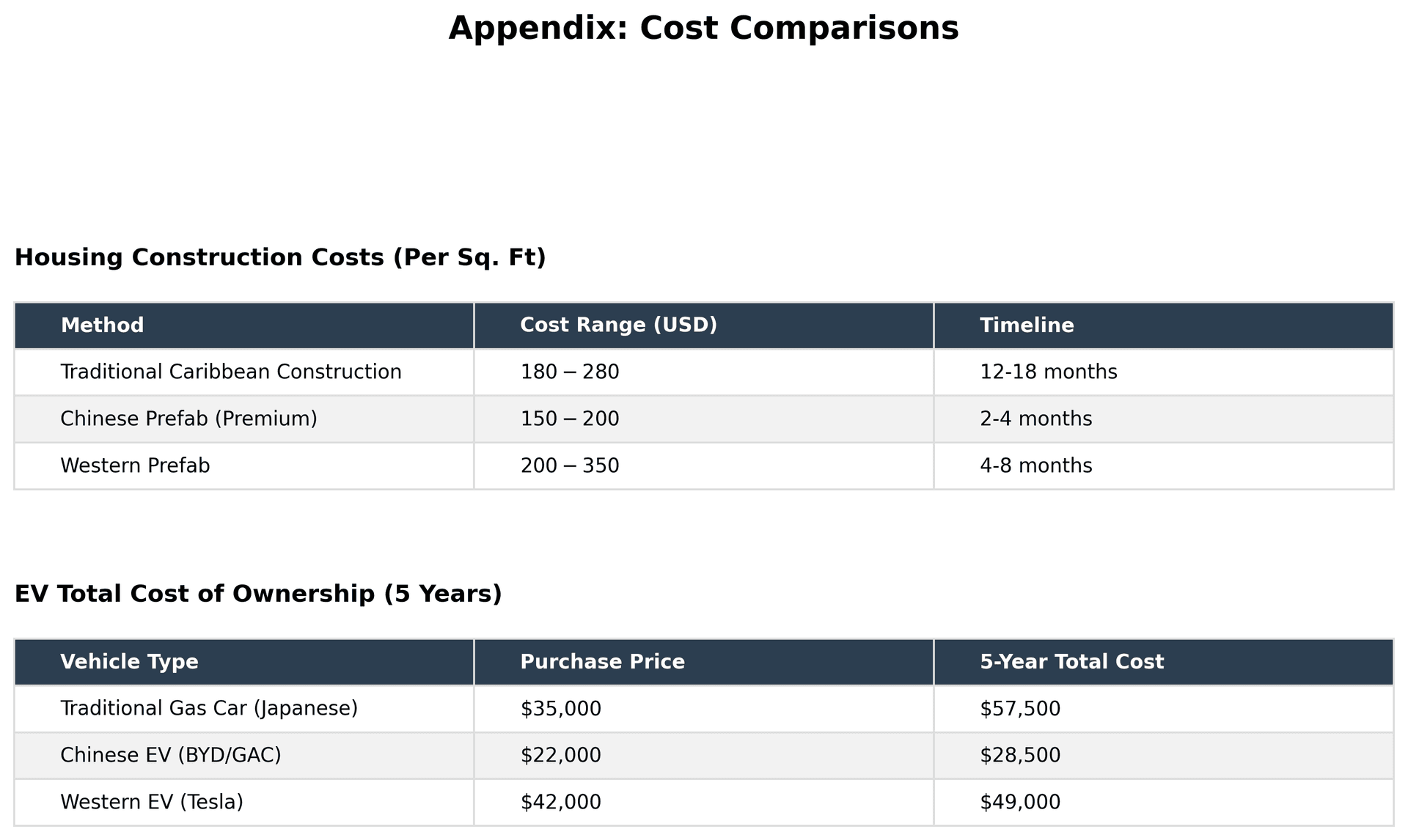

· Cost: A standard modular unit costs under $12,000 delivered to Jamaica. A full 2,000 sq ft home can be built for $200,000—luxury finishes included.

· Speed: Factory construction means no rain delays. Assembly takes weeks.

· Resilience: These aren't flimsy shacks. Leading manufacturers engineer homes to withstand Category 4 hurricanes, using corrosion-resistant materials designed for our salty air.

Companies like Weifang Zhonglei and DeepBlue Smarthouse are already shipping thousands of these units globally. For the Caribbean, this could be the silver bullet for our housing shortage.

Case Study 2:

The Electric Vehicle Revolution

Chinese automotive brands like BYD and GAC are not just entering the Caribbean market; they are reshaping it. In places like Jamaica and Barbados, these cars are becoming a common sight.

Why It Matters

It comes down to economics. Chinese EVs are significantly cheaper than their Western or Japanese counterparts. In a region where gas prices are punishing, the math is simple: lower purchase price + lower fuel costs = massive savings for Caribbean families.

The Quality Question: BYD is now Tesla's biggest rival for a reason. Their "Blade Battery" technology is world-class, retaining 80% capacity after 8 years. While their software might lag slightly behind Tesla, the build quality and safety ratings (5-star Euro NCAP) are undeniable.

Case Study 3:

Construction Materials

China dominates the global supply of steel, cement, and glass. This dominance allows for economies of scale that Western suppliers can't touch—often 30-50% cheaper.

The Good, The Bad, and The Ugly

However, this is where caution is most needed. Quality varies wildly. We've seen the horror stories, like the unfinished airport expansion in Guyana or the Baha Mar disputes. The lesson is clear: You get what you inspect, not what you expect.

Successful procurement requires:

1. 1. Detailed specifications (don't leave wiggle room).

2. 2. Third-party testing before shipment.

3. 3. Staged payments tied to quality verification.

The Geopolitical Elephant in the Room

We cannot ignore the politics. The U.S. views China's growing footprint in the Caribbean with suspicion. But for Caribbean nations, this isn't about picking sides in a superpower rivalry; it's about survival and development.

The Pragmatic Approach: We need to diversify. We should engage with China for cost-effective infrastructure and housing while maintaining our strong, traditional ties with the U.S., Canada, and Europe. It’s not "either/or"—it’s "both/and."

A Framework for Success: How to Buy Smart

If we are going to pivot to Chinese products, we need to do it professionally. Here is the 5-step framework for sourcing responsibly:

4. Strategic Supplier Selection: Only work with "Verified" suppliers who have international certifications and a track record in tropical climates.

5. Rigorous Quality Assurance: Never skip inspections. Hire third-party firms (like SGS or Bureau Veritas) to inspect goods before they leave the factory. It costs a few hundred dollars to save millions in mistakes.

6. Ironclad Contracts: Use contracts that are enforceable in China, with clear penalties for quality failures.

7. Total Cost of Ownership (TCO): Don't just look at the sticker price. Factor in shipping, duties (which can be high), and maintenance.

8. Build Local Capacity: Train our local engineers and builders to work with these new materials and systems.

Conclusion: The Path Forward

The Caribbean stands at a crossroads. We can stick to the status quo—complaining about high costs, watching our infrastructure crumble, and waiting for aid that never quite fills the gap. Or, we can take a bold, strategic step.

Chinese manufacturing is neither a magic wand nor a poison pill. It is a tool. Like any tool, its value depends on the skill of the user. If we approach this with naivety, we will get burned. But if we approach it with sophistication—demanding quality, enforcing standards, and negotiating hard—we can build the homes, roads, and energy grids our people deserve.

The stereotype of "cheap Chinese junk" is a relic of the past. The opportunity to build a modern, affordable Caribbean is right here, right now. The only question is: Are we smart enough to seize it?

Appendix: Cost Comparisons

About the Author: Mick Rodgers is a Caribbean development analyst and consultant specializing in infrastructure, trade, and sustainable development. This article represents independent analysis.